News OverviewNews

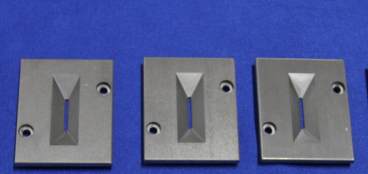

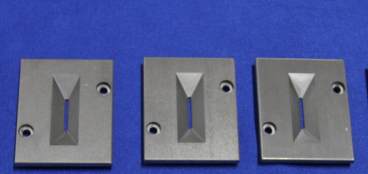

ion implanted tungsten parts

Ion implantation is a kind of high technology for surface modification of materials, which has been developed vigorously in the last 30 years. It can optimize the surface properties of materials or obtain some new excellent properties. Because of the unique and outstanding characteristics of this high technology, it is a very important technology in modern integrated circuit manufacturing. He uses ion implanters to dope semiconductors and change their electrical conductivity and transistor structure.

Due to the ion implantation, the ion source converted into plasma ions will produce a working temperature of more than 2000 degrees, the ion beam eruption will also produce a lot of ionic kinetic energy, the general metal will soon melt, so the quality and density are relatively large inert metal, in order to maintain the direction of the ion beam eruption and can only add the durability of the component. Tungsten material has the advantages of stable high temperature chemical properties, small thermal denaturation and long service life, and has become the first choice of ion source parts and consumables for ion implanters in the semiconductor industry. The shielding cylinder of the emission cathode, the emission panel, the center fixed rod, and the wire plate in the arc room are all called ion implanted tungsten parts.