News OverviewNews

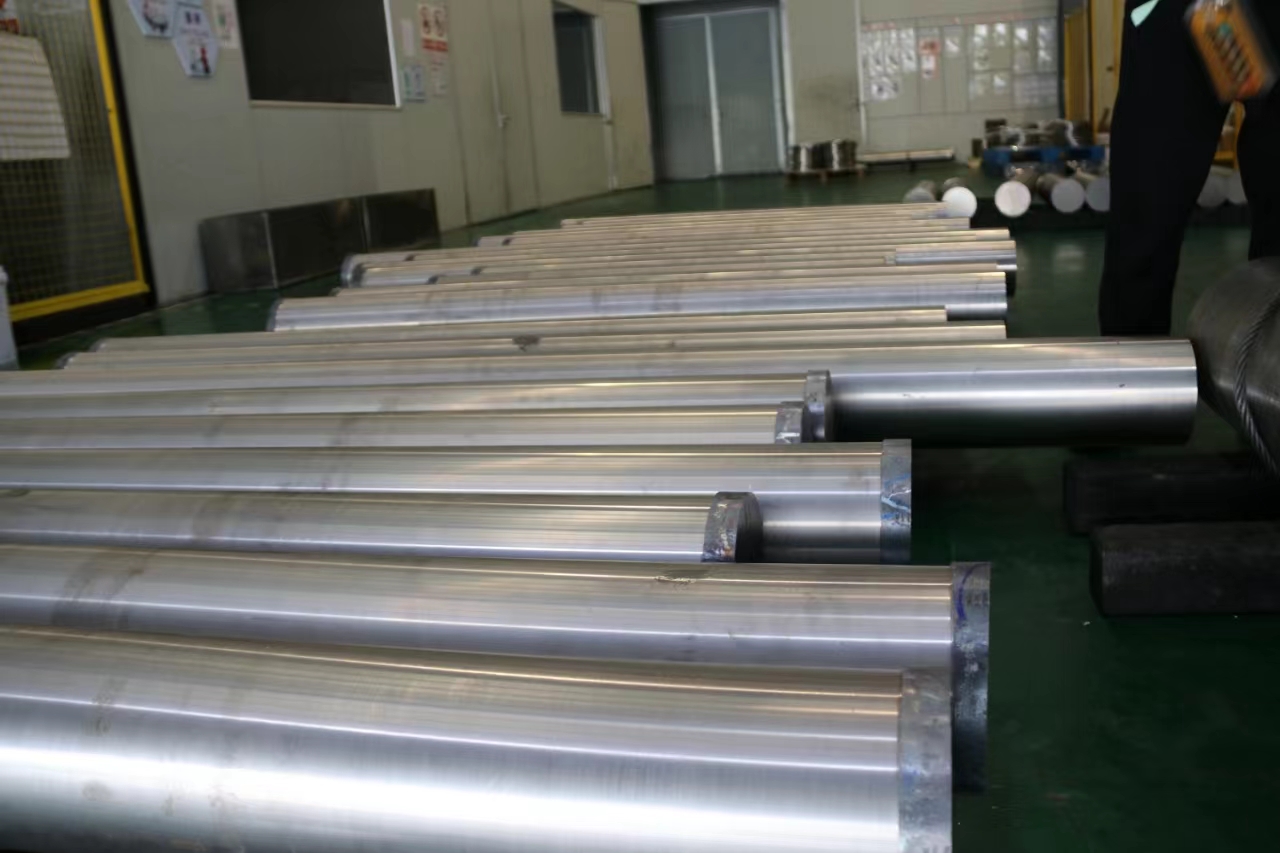

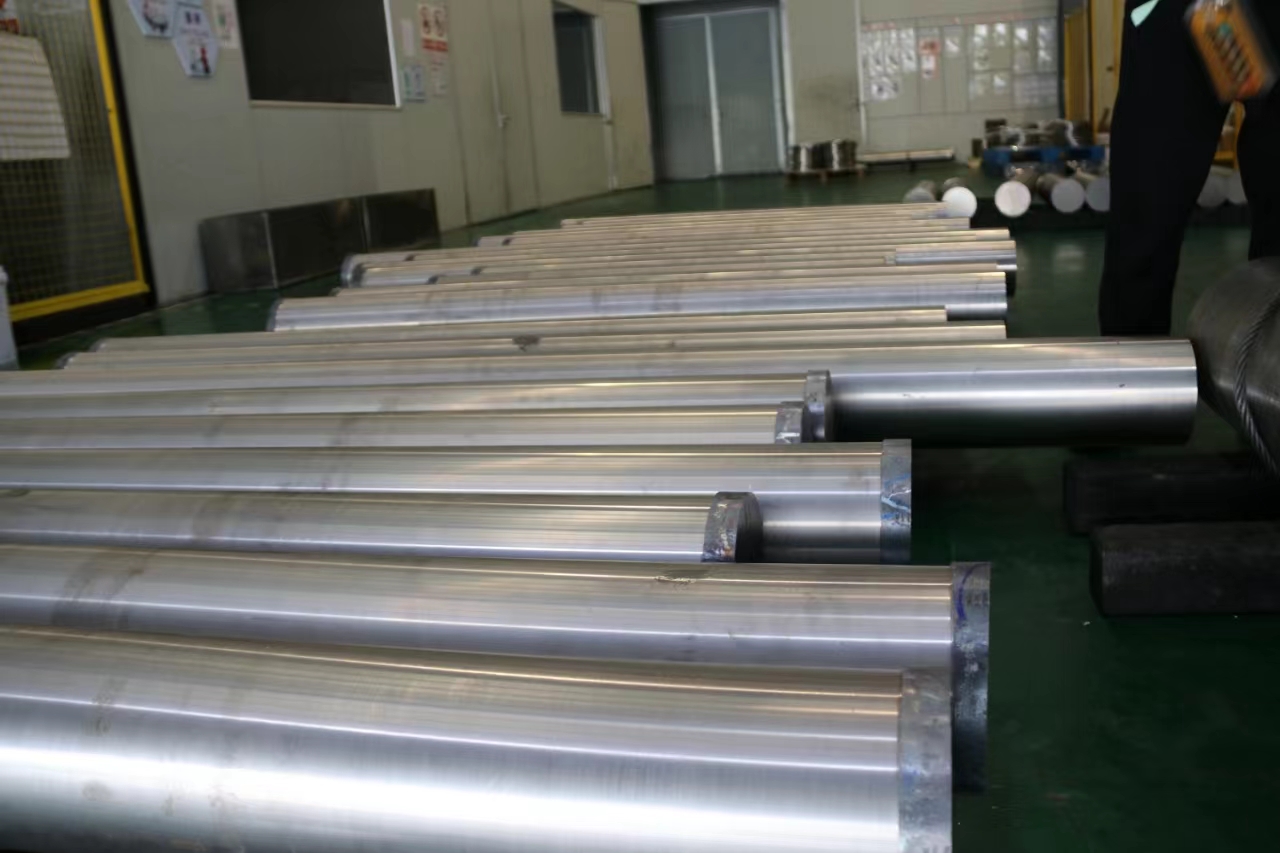

High purity titanium Rod

At present, the main application areas of low-oxygen and high-purity titanium on the market are semiconductors and planar display targets, in addition to aerospace uses and biomedical raw materials. The preparation of high purity titanium is mainly through upgrading kroll sponge titanium reduction technology, titanium tetrachloride and magnesium ingots through kroll method into high purity titanium sponge, and then through electrolysis method to prepare high purity point hydrolysis titanium, and then through electron beam melting to make high purity titanium ingots, so that our high purity titanium processing products are also made accordingly. Our raw titanium ingot is usually a diameter of 700mm, a single weight of 3 tons of high purity titanium ingot, the grain structure of our raw material can be controlled to 100-150um, the grain structure of the finished target can be controlled to 50-100um. Our main products: high purity titanium targets, currently involved in the purity of 4N5,5N etc; There are also some high purity titanium particles, if you are interested in such products, welcome to contact me in time.