News OverviewNews

3D printing Titanium productes

At present, most of the manufacturing equipment for 3D printed titanium metal products is powder 3D printers. During the manufacturing process, the machine will first spread a thin layer of spherical titanium powder on the powder bed, and then use a carbon dioxide laser for sintering. Finally, it will be repeated, layer by layer. Layers are added until the entire product is complete. The surface of such metal parts is not smooth, but has a gray rough shape. However, now the surface smoothness can be achieved through back-end surface treatment on the market. So the question is, how is this spherical titanium powder that is indispensable in the 3D printing market made?

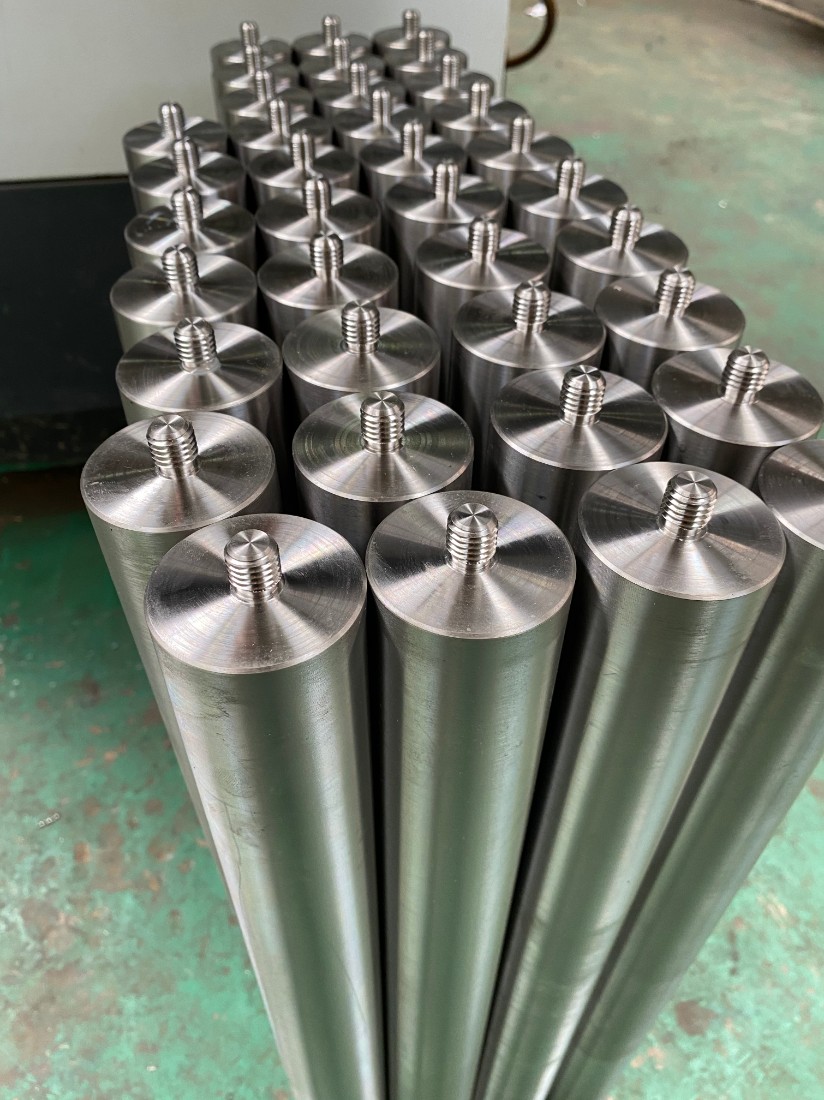

At present, the main preparation methods of spherical titanium powder include sponge titanium mechanical crushing method, atomization method and plasma rotating electrode method. Among them, the mechanical crushing method refers to a method of crushing metal or alloy into powder through the action of simple machinery. Since titanium has toughness, the shape of the powder obtained by this method is irregular, and the pollution during the crushing process reduces the purity of titanium. lower, so this method is not accepted by the market. The atomization method is a method that uses high-speed airflow to impact and break the molten metal flow and rapidly cool it to form metal powder. During the atomization process of this method, the molten metal is volatile and the powder obtained is mostly hollow particles. The plasma rotating electrode method is a kind of consumable electrode made of metal or alloy. The end surface of the electrode is heated by an arc and melted into a liquid. The centrifugal force of the high-speed rotation of the electrode throws the liquid out and crushes it into small droplets, and finally cools into a powder. method. The powder produced by this method has better sphericity. Therefore, this kind of mature spherical titanium powder powder making line is currently used in the domestic market, and the raw materials used in these powder making are titanium rods and titanium wires as raw materials.

However, the selection of titanium rod powdering raw materials is not arbitrary. Usually the chemical composition of titanium rods has special requirements for the content of O and N. Considering the efficiency of the use of electrode rods, threaded connections are usually used in China. After docking, ensure good straightness. Usually the straightness is controlled at 0.3mm/m. In addition, the surface quality of the electrode rod is also very important. There should be no defects or cracks on the surface, which will affect the purity and milling efficiency. The materials involved mainly include: TC4/Grade5, TA15 etc.

Of course, the current common specification for wire material is 3.175mm in diameter. Spherical titanium powder can also be prepared through the plasma atomization method for 3D titanium product printing.